The Ultimate Guide to Welding: Techniques, Applications, and Best Practices

The Ultimate Guide to Welding: Techniques, Applications, and Best Practices

Welding is an essential skill that holds together the infrastructure of our world—literally. From towering skyscrapers to everyday appliances, welding is responsible for creating strong, durable joints that stand the test of time. But what exactly is welding, and why is it so vital in various industries? Whether you’re a professional welder or a curious beginner, this guide will walk you through the ins and outs of welding, covering everything from basic techniques to advanced practices.

What is Welding?

Welding is a fabrication process that joins two or more materials, typically metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Unlike other bonding techniques like soldering and brazing, welding melts the base materials. This process often involves adding a filler material to form a pool of molten material that cools to become a strong joint.

Types of Welding Processes

Welding isn’t a one-size-fits-all process. There are several different welding techniques, each suited to specific applications and materials. Here’s an overview of the most common welding methods:

- TIG Welding (Tungsten Inert Gas):

- Also Known As: Gas Tungsten Arc Welding (GTAW)

- Process: TIG welding uses a non-consumable tungsten electrode to produce the weld. The process is protected by an inert gas, typically argon.

- Best For: Thin materials like stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys.

- Advantages: Provides high-quality, precise welds; ideal for thin or delicate materials.

- Stick Welding:

- Also Known As: Shielded Metal Arc Welding (SMAW)

- Process: Stick welding uses a consumable electrode covered with a flux to lay the weld. An electric current creates an arc between the electrode and the materials being joined.

- Best For: Iron, steel, aluminum, and nickel.

- Advantages: Versatile and effective in outdoor or windy conditions; doesn’t require shielding gas.

- Flux-Cored Arc Welding (FCAW):

- Process: Similar to MIG welding, but uses a special tubular wire filled with flux instead of a solid wire. This can be used with or without shielding gas.

- Best For: Heavy-duty industrial applications, thicker materials, and outdoor work.

- Advantages: High welding speed and portability; effective on dirty or rusty materials.

- Plasma Arc Welding:

- Process: Plasma arc welding is similar to TIG welding but uses a plasma torch to create a more precise arc. It’s used for thin or precision work.

- Best For: Aerospace applications, electronics, and thin materials.

- Advantages: High precision and control; can produce very clean welds.

- Laser Welding:

- Process: Laser welding uses a focused laser beam to melt the materials at the joint. It’s often used in automated systems for high precision.

- Best For: Automotive, medical devices, and electronics.

- Advantages: High precision, minimal heat-affected zone, and capable of welding small, intricate parts.

Common Applications of Welding

Welding is ubiquitous, touching nearly every industry. Here are some of the most common applications:

- Construction: Welding is vital in the construction of buildings, bridges, pipelines, and other infrastructures. It ensures the structural integrity of steel frameworks and supports.

- Automotive Industry: From car frames to exhaust systems, welding is crucial in manufacturing vehicles. It provides the durability and strength needed to withstand daily use.

- Aerospace: In the aerospace industry, welding is used to assemble aircraft components that must meet stringent safety and performance standards.

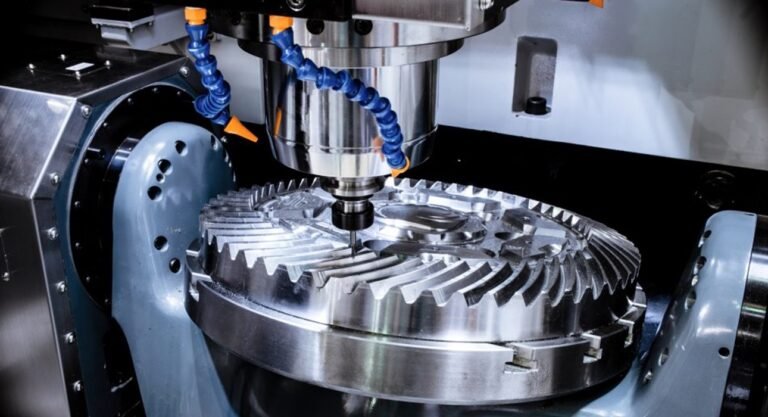

- Manufacturing: Welding plays a key role in creating products ranging from household appliances to industrial machinery. It’s essential in ensuring that these products are both functional and durable.

- Shipbuilding: Welding is heavily used in the construction of ships and submarines. It ensures that the vessels are watertight and able to withstand harsh marine environments.

- Art and Sculpture: Beyond industrial uses, welding is also an art form. Artists use welding to create sculptures, metal artwork, and other creative expressions.

Best Practices for Quality Welding

To ensure strong, reliable welds, it’s crucial to follow best practices. Here are some tips that can help:

- Proper Preparation: Clean the materials thoroughly before welding to remove any dirt, rust, or oils that could weaken the weld. Use a wire brush or grinder if necessary.

- Choose the Right Technique: Different materials and applications require different welding techniques. Make sure you’re using the method best suited to your project.

- Control Heat Input: Too much heat can cause warping or burn-through, while too little can result in weak welds. Adjust your settings based on the thickness and type of material.

- Use the Right Filler Material: Ensure that the filler material matches the base materials. Using the wrong filler can result in weak or brittle welds.

- Practice Good Post-Weld Care: After welding, inspect the welds for any defects like cracks or pores. Depending on the application, you may also need to grind, sand, or coat the weld for added durability and appearance.

- Safety First: Always wear appropriate safety gear, including a welding helmet, gloves, and protective clothing. Ensure proper ventilation to avoid inhaling harmful fumes.

Welding Safety Tips

Welding is a potentially dangerous activity, and safety should always be a top priority. Here are some critical safety tips to keep in mind:

- Wear Protective Gear: Always wear a welding helmet with the proper shade lens, gloves, flame-resistant clothing, and safety glasses.

- Ensure Proper Ventilation: Welding can produce harmful fumes and gases. Work in a well-ventilated area or use exhaust systems to remove fumes.

- Protect Against Fire Hazards: Keep flammable materials away from the welding area and have a fire extinguisher nearby.

- Be Aware of Electrical Hazards: Ensure that your welding equipment is properly grounded and in good condition. Avoid welding in wet or damp conditions to reduce the risk of electric shock.

- Stay Trained and Informed: Regularly update your skills and knowledge through training and certification programs. Staying informed about the latest safety standards and welding techniques can prevent accidents and improve the quality of your work.

The Future of Welding: Trends and Innovations

The welding industry continues to evolve, with new technologies and techniques emerging to meet the demands of modern manufacturing. Here’s a glimpse into the future of welding:

- Automation and Robotics: Automated welding systems and robots are becoming more common, especially in high-volume production environments. These systems offer consistent quality and can operate around the clock.

- Laser and Hybrid Welding: As laser welding technology advances, it’s being combined with traditional methods to offer even greater precision and efficiency. Hybrid welding systems can weld thicker materials more quickly while maintaining high quality.

- 3D Printing with Metal: Additive manufacturing, or 3D printing, is starting to incorporate welding techniques to build metal parts layer by layer. This approach allows for the creation of complex geometries that are difficult or impossible to achieve with traditional welding.

- Sustainable Practices: The industry is increasingly focused on reducing waste and energy consumption. Techniques like cold metal transfer (CMT) welding are gaining traction for their energy efficiency and reduced heat input.

FAQs About Welding

Q: What is the strongest type of weld?

A: TIG welding is generally considered to produce the strongest and most precise welds, especially on thin or delicate materials. However, the strength of a weld also depends on the material, joint design, and the skill of the welder.

Q: Can welding be done outdoors?

A: Yes, certain types of welding, like stick welding, are well-suited for outdoor environments. These methods don’t rely on shielding gases that can be blown away by wind.

Q: How long does it take to learn welding?

A: The time it takes to learn welding varies depending on the complexity of the techniques and the individual’s skill level. Basic welding skills can be learned in a few weeks, but mastering advanced techniques may take years of practice.

Q: What materials can be welded?

A: Welding can be performed on a wide range of materials, including steel, aluminum, stainless steel, brass, copper, and titanium. The choice of welding method often depends on the material being welded.

Q: Is welding dangerous?

A: Welding can be dangerous if proper safety precautions are not taken. Risks include burns, eye damage, respiratory issues, and electric shock. However, with the right training, equipment, and safety practices, these risks can be minimized.

Final Thoughts

Welding is a critical skill that plays a fundamental role in numerous industries. Whether you’re building bridges, manufacturing cars, or creating art, mastering welding techniques and following best practices ensures that your work is strong, durable, and safe. As technology advances, the field of welding continues to evolve, offering new opportunities for those skilled in this essential trade.