Sheet Metal 101: Essential Guide to Materials, Applications, and Techniques

Sheet Metal 101: Essential Guide to Materials, Applications, and Techniques

Sheet metal might seem like just another material, but it plays a crucial role in many industries. From the car you drive to the appliances in your kitchen, sheet metal is everywhere. But what exactly is sheet metal, and how is it used? Let’s dive in and break down everything you need to know, whether you’re a curious beginner or an industry professional looking to brush up on the basics.

What Is Sheet Metal?

Sheet metal is a flat piece of metal that has been industrially processed to a thin thickness. Typically, sheet metal is less than 6mm thick, though it can vary depending on its intended use. The term “sheet” refers to its form, as opposed to bars, rods, or plates, which are other common metal forms.

Common Types of Sheet Metal

- Steel: Widely used due to its strength and durability. Steel sheet metal comes in two main types:

- Carbon Steel: Strong and malleable, often used in construction.

- Stainless Steel: Resistant to rust and corrosion, ideal for environments exposed to moisture.

- Aluminum: Known for being lightweight yet strong. It’s resistant to corrosion, making it perfect for aerospace and automotive industries.

- Copper: Offers excellent electrical conductivity and is often used in electrical applications. It also has a unique aesthetic appeal, especially in architecture.

- Brass: A combination of copper and zinc, brass is known for its malleability and acoustic properties. It’s frequently used in musical instruments and decorative elements.

- Titanium: Extremely strong and lightweight, titanium is often used in aerospace and medical applications.

Applications of Sheet Metal

Sheet metal’s versatility means it’s used across various industries. Here are some key applications:

- Automotive Industry: From car bodies to exhaust systems, sheet metal is crucial in vehicle manufacturing.

- Construction: Sheet metal is used in roofing, gutters, ductwork, and even decorative elements like facades.

- Aerospace: Lightweight yet strong metals like aluminum and titanium are essential in aircraft manufacturing.

- Electronics: Copper sheet metal is widely used in electrical components for its conductivity.

- Home Appliances: From refrigerators to ovens, sheet metal forms the outer casing and internal components of many household appliances.

Sheet Metal Fabrication Techniques

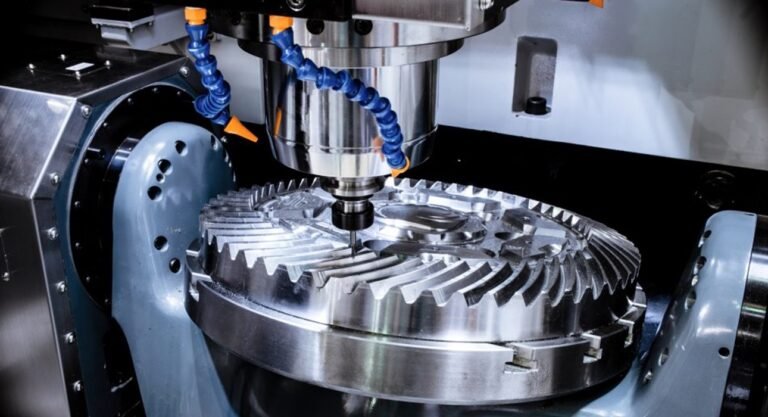

The process of turning raw sheet metal into usable products involves several key techniques. Here are the most common methods:

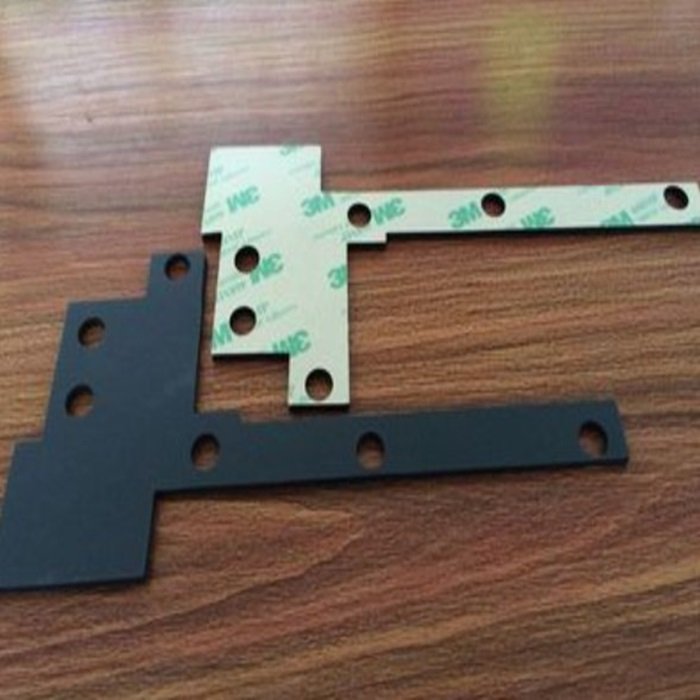

- Cutting: The first step in sheet metal fabrication is cutting the metal to the desired shape and size. This can be done through:

- Shearing: Using a cutting blade to slice through the metal.

- Laser Cutting: A precise and efficient method using a high-powered laser to cut the metal.

- Waterjet Cutting: Using a high-pressure jet of water mixed with abrasive materials to cut through metal.

- Bending: After cutting, the sheet metal is often bent into the required shape. This can be done through:

- Press Braking: Applying pressure along a straight line to bend the metal at a specific angle.

- Roll Bending: Passing the metal through rollers to create a curve or cylinder.

- Stamping: Involves pressing or stamping the sheet metal into a specific shape using a die. This is common in mass production for parts like car panels.

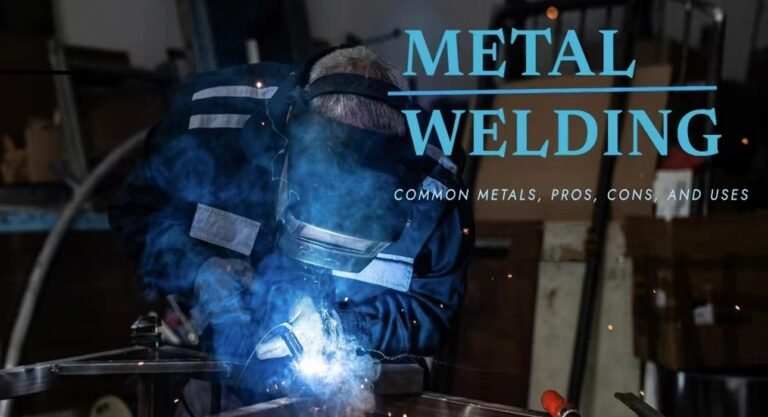

- Welding: Welding joins two or more pieces of sheet metal together. This is crucial in constructing larger structures like buildings or vehicles.

- Punching: Punching involves using a die to create holes or cut-outs in the sheet metal. This technique is often used in manufacturing components that require precise holes, like electrical enclosures.

- Finishing: The final step involves treating the metal surface to improve its appearance or resistance to corrosion. This can include:

- Painting: Applying a protective and decorative coating.

- Galvanizing: Coating the metal with zinc to prevent rust.

- Anodizing: An electrochemical process that enhances the metal’s surface.

Benefits of Using Sheet Metal

There’s a reason sheet metal is so widely used—it offers several key advantages:

- Durability: Sheet metal is known for its strength and long-lasting properties.

- Versatility: It can be shaped, cut, and joined in countless ways, making it suitable for a variety of applications.

- Cost-Effective: Especially when produced in large quantities, sheet metal can be an economical choice.

- Lightweight: Despite its strength, sheet metal is relatively light, particularly aluminum and titanium, making it easy to transport and work with.

- Sustainability: Metals like aluminum are highly recyclable, making sheet metal a more sustainable option in manufacturing.

The Future of Sheet Metal: Innovations and Trends

As technology advances, so too does the field of sheet metal fabrication. Here are some trends and innovations to keep an eye on:

- Automation: With the rise of smart manufacturing, automated systems are increasingly used in sheet metal fabrication. This improves precision, efficiency, and safety.

- 3D Printing with Metals: While still in its early stages, 3D printing with metal powders is opening up new possibilities for creating complex sheet metal components.

- Sustainable Practices: As industries push toward sustainability, there’s a growing emphasis on using recycled materials and reducing waste in sheet metal production.

FAQs About Sheet Metal

Q: How thick is sheet metal typically?

A: Sheet metal is generally less than 6mm thick, though thickness can vary depending on the specific application.

Q: What’s the difference between sheet metal and plate metal?

A: The main difference is thickness. Plate metal is thicker (usually more than 6mm), while sheet metal is thinner.

Q: Can sheet metal be recycled?

A: Yes, most types of sheet metal, particularly aluminum and steel, are highly recyclable.

Q: What industries use sheet metal the most?

A: Sheet metal is heavily used in the automotive, aerospace, construction, electronics, and home appliance industries.

Final Thoughts

Sheet metal is a cornerstone of modern manufacturing and construction, offering a combination of strength, versatility, and cost-effectiveness that few other materials can match. Whether you’re working on a large-scale construction project or a small DIY task, understanding the basics of sheet metal can help you make the right decisions for your project.

By staying informed about the materials, techniques, and innovations in the field, you can leverage sheet metal’s full potential in whatever application you’re working on.